We've known what 'repairable' means for a long time - now there's an EU standard for it!

Last week, three years of wrangling with industry finally paid off, as European standard EN 45554:2020 was published. This official document with an unexciting name describes "general methods for assessing the possibility of repairing, reusing and upgrading energy-related products." In plain English, it's a benchmark for how easy it should become to repair an electrical appliance. It's also a major milestone in the fight for a fair(er) framework for repair.

Why is this a big deal?

We want to have electrical appliances that we own repaired at a reasonable price so that we can use them longer. This is important not only because we want to save money, but also because the production of new products is a huge and underestimated driver of climate change. So if we want to avoid heating up our planet further, we need to stop producing disposable electronics and start repairing more. And we need to do it now.

The problem is that industry is not yet doing this on its own. Therefore, regulatory policy must intervene, ban non-repairable products and help consumers identify the most durable products to enable them to make better purchasing decisions. And in the EU, our policymakers have long since decided to do just that.

But here's the rub: These politicians don't know what a repairable product is. If they ask the manufacturers, they will all tell you that their products are repairable. If they ask us, some devices are clearly more repairable than others, and some are frankly not repairable at all.

So, in order to regulate repairability, we needed a generally accepted method to measure how repairable energy-related products are. That is what a CEN-CENELEC working group (JTC 10, WG 3, responsible for Repair, Re-Use and Upgrade) has been developing over the last three years. I have chaired this working group for almost 2 years to ensure that the interests of industry lobbyists, despite numerical superiority, are balanced with the interests of NGOs, Commission and Ministry representatives.

It was decided early on that the new standard would be a toolbox, a collection of criteria and methods from which to choose depending on the product. First, we established criteria to decide which parts of the product the assessment should focus on, whether physical parts or firmware or software. Then we identified different dimensions of repairability. Some are characteristics of the product itself, such as the type of fasteners and tools required to disassemble the product. Some are related to the specific knowledge of manufacturers: for example, diagnostic software, without which independent repairers can no longer even clear the error code on the display of a washing machine. Or the availability of spare parts and technical information.

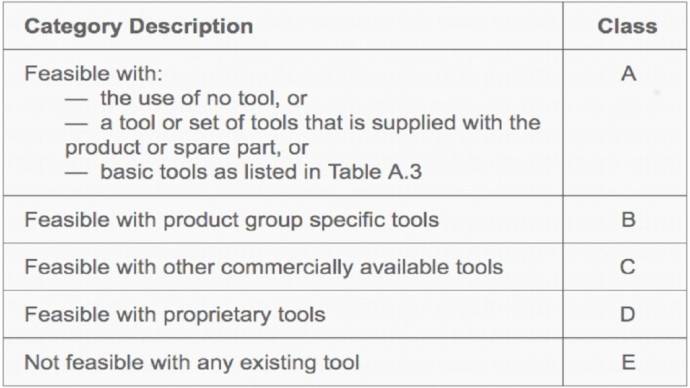

Good, better, best: The most repairable products are those that can be disassembled without, or with only a few simple tools. (Table from EN 45554:2020, which classifies repairability according to the tools required).

We then created rating tables for all these aspects. Finally, we developed a flexible aggregation formula to merge all the identified parameters into a single repairability assessment, while adapting the specific criteria and their weights to the type of product being assessed.

It was not easy to reach a consensus on all this. There was an intense debate on every aspect. The vast majority of the working group were representatives of manufacturers. While some seemed willing to improve their products and services, some just wanted to make sure that what they were already making remained sellable. And frankly, some seemed determined to sabotage the process at every step.

Nevertheless, those waiting for change made progress. We wrote proposal after proposal, and several drafts were rejected by national representatives*. But in November 2019, the text was finally approved - and we now have an official standard for assessing repairability.

This is a milestone. For the first time ever, our position on repairability is not just the opinion of the repair and service center R.U.S.Z and some organizations close to us like iFixit. Instead, the EU now has a widely accepted document that establishes a hierarchy of repair options. It is now official, for example, that snaps that break off when trying to open a product make it unrepairable. Or that using exotic types of screws in a product complicates maintenance and repair, making it more expensive. If manufacturers make their service manuals available only to authorized factory service and a few service partners, they will have problems in the future. And if they really want their products to be repaired as often as possible, they should supply spare parts to anyone who asks for them..

We have been fighting for this for many years. It started with the Austrian standard ONR 192102:2006, developed under the leadership of R.U.S.Z technicians, and its update in 2014, together with the responsible ministry BMNT and the Austrian Standards Institute ASI. ONR 192102:2014 "Quality marks for durable electrical and electronic equipment designed for easy repair" served as a template for the EU standard. Now we also have it in black and white in EN 45554:2020!

But we are not done yet. Now this toolbox needs to be applied. This requires product group-specific standards and independent test methods. The latter are being (co-)developed by R.U.S.Z in the PROMPT project.

Now that we all agree on what "repairable" actually means, there are no more excuses. From 2025 onwards, there will only be durable, repair-friendly designed e-appliances!